Keeping your plastering tools clean is essential for maintaining their performance and longevity.

We will discuss the importance of cleaning plastering tools, the necessary tools for cleaning, and step-by-step instructions on how to clean them effectively.

From rinsing off excess plaster to storing them properly, we will cover everything you need to know to keep your tools in top condition.

We will provide tips on how often to clean your tools and how to maintain them for optimal use. Let’s get started on keeping your plastering tools in great shape!

Uncover more: How To Plaster A Wall

Why Is It Important To Clean Plastering Tools?

Cleaning plastering tools is crucial to maintain their quality and ensure smooth finishes in plasterwork projects. Proper cleaning not only extends the tools’ lifespan but also enhances the final result of plastering jobs.

When tools are not cleaned adequately, old plaster residue can harden and accumulate on them, leading to imperfections in the finish and affecting the overall quality of the work. This can result in rough patches or uneven surfaces that compromise the visual appeal and durability of the plastered walls or ceilings. By regularly cleaning the tools, you prevent these issues and uphold a professional standard in your craftsmanship.

Clean tools are essential for achieving a flawless, professional finish that will impress clients and stand the test of time.

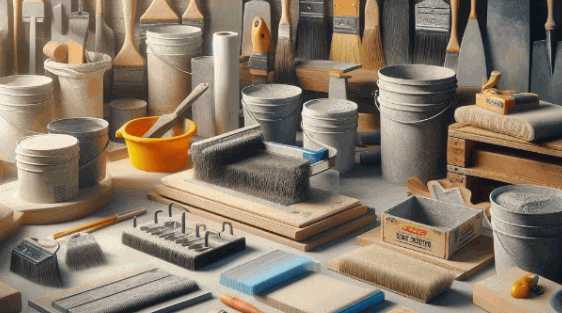

What Tools Are Needed For Cleaning Plastering Tools?

To clean plastering tools effectively, you will need various items, including a bucket, scraper, wire brush, cleaning solution, and water. These tools are essential for maintaining the quality and functionality of your plastering equipment.

Plus the basic items mentioned, a trowel is another crucial tool for cleaning plastering equipment. The scraper helps remove excess plaster, while the wire brush aids in scrubbing off tough residue. The cleaning solution can be a mixture of mild soap and warm water, ensuring thorough cleaning without damaging the tools. It is important to regularly clean and dry your tools to prevent rust or deterioration. Proper maintenance not only enhances the longevity of your tools but also ensures smoother and more efficient plastering work in the future.

Bucket

A bucket is a fundamental item for cleaning plastering tools efficiently, allowing you to manage water usage effectively while washing off excess plaster residues.

By using a bucket, you can control the amount of water you use, preventing wastage and ensuring you only use what is necessary for the cleaning process. This not only helps in conserving water but also saves you money in the long run by reducing utility bills.

To optimize water consumption, consider filling the bucket only to the required level, avoiding unnecessary overflow. You can reuse the water in the bucket for multiple rounds of cleaning before disposing of it, maximizing its efficiency

Scraper

The scraper is a versatile tool essential for removing dried or stubborn plaster residues from surfaces and tools. It can be aided with paste wax to facilitate smoother cleaning.

When using a scraper for cleaning tasks, applying a thin layer of paste wax on the tool’s edge can help reduce friction and enhance the scraping action. This simple yet effective technique makes it easier to glide the scraper over the dried plaster, allowing for more efficient removal without causing damage to the underlying surface.

The paste wax acts as a lubricant, enabling the scraper to slide smoothly along the residue, ensuring a thorough cleaning process. The wax helps to protect the scraper’s edge from wear and tear, prolonging its lifespan and maintaining its effectiveness over time.

Wire Brush

A wire brush is an essential tool for scrubbing off tough plaster residues from tools effectively. Utilizing wash stations can enhance the cleaning process when using a wire brush.

When working with plaster, tools often accumulate stubborn residues that can be challenging to remove, impacting their performance if not cleaned properly. A wire brush, with its stiff bristles, provides the necessary abrasive power to break down and remove hardened plaster residues effectively.

The incorporation of wash stations into workspaces simplifies the cleaning process by offering designated areas equipped with the necessary tools and cleaning solutions. This ensures that after using a wire brush on plastering tools, they can be thoroughly cleansed, maintaining their longevity and functionality.

Cleaning Solution

Using a suitable cleaning solution is essential for effectively removing plaster residues from tools. Following tutorials by experts can guide you in selecting the right solutions for cleaning.

A seasoned professional in the plastering industry emphasizes that choosing the proper cleaning product can significantly impact the longevity and performance of your tools.

With expert advice, you can learn about the specific ingredients and formulations that are most effective in dissolving hardened plaster without damaging your equipment. It’s crucial to pay attention to the compatibility of the solution with the material of your tools to avoid any corrosive reactions.

By incorporating recommendations into your cleaning routine, you can ensure that your plastering tools remain in top condition for your next project.

Water

Water is a key component in the cleaning process of plastering tools, and it can be enhanced by incorporating products like DAZ washing powder for effective cleaning results.

Using DAZ washing powder can help break down stubborn residues and dirt from the tools, ensuring a thorough cleaning process. The combination of water and a quality cleaning product like DAZ washing powder can significantly improve the efficiency and outcomes of cleaning plastering tools.

By utilizing a dedicated cleaning solution like DAZ washing powder, you can achieve a more pristine finish on your tools, removing any grime or build-up that traditional cleaning methods might struggle to tackle.

How To Clean Plastering Tools?

Cleaning plastering tools involves a series of steps to ensure their longevity and maintain the quality of plasterwork. Following proper cleaning techniques is essential for achieving a smooth finish in your projects.

Begin by gathering all the necessary materials such as a bucket, warm water, detergent, scrub brushes, and clean clothes.

Techniques such as soaking the tools in warm soapy water, scrubbing off excess plaster, and wiping them dry with a cloth can help remove hardened residues effectively.

Materials like vinegar or specialized cleaning solutions can be used for tougher stains. Keeping tools clean not only extends their lifespan but also ensures they perform optimally, resulting in professional-looking plasterwork.

Rinse Tools With Water

Begin the cleaning process by rinsing your plastering tools with water to remove loose plaster residues and prepare them for thorough cleaning. This step is crucial, especially on a busy construction site.

Not only does rinsing tools with water effectively eliminate the primary layer of debris, but it also helps in reducing the overall water consumption during the subsequent cleaning stages. By rinsing off the initial grime, you make the cleaning process more efficient and eco-friendly. This method is highly suitable for construction sites due to its simplicity and quick execution. It ensures that tools are ready for the next use without compromising on cleanliness or wasting excess water.

Scrape Off Excess Plaster

Use a scraper to remove excess plaster from your tools, ensuring that they are free from build-up that can affect the quality of your plastering jobs. This small investment of time can yield significant returns in job outcomes.

By taking the time to scrape off excess plaster, you are not only maintaining the integrity of your tools but also ensuring a smoother and more precise finish in your plastering projects.

- This simple step can prevent inconsistencies in the application of plaster, resulting in a more professional and polished look.

- By keeping your tools clean, you are extending their lifespan, saving you money in the long term.

Investing a few extra minutes in this practice can lead to a higher level of craftsmanship and customer satisfaction.

Use Wire Brush To Remove Stubborn Plaster

Employ a wire brush to tackle stubborn plaster residues on your tools, ensuring a clean surface that contributes to achieving a smooth finish in your plasterwork. The wire brush is effective in handling tough cleaning tasks.

Its bristles are designed to penetrate deeply into the surface, loosening and removing even the most stubborn remnants of plaster.

By diligently using a wire brush, you can ensure that your tools are free from any residue that could compromise the smooth finish of your plasterwork.

The wire brush’s sturdy construction allows for repeated use, making it a reliable tool in your arsenal for maintaining the quality of your equipment and ensuring a professional outcome.

Soak Tools In Cleaning Solution

Submerge your plastering tools in a suitable cleaning solution to dissolve the remaining plaster residues effectively. Following tutorials on proper soaking techniques can optimize the cleaning process.

By immersing the tools in a cleaning solution, you allow the stubborn plaster residues to loosen, making it easier to scrub them off later. The soaking process also helps prevent the accumulation of dried-on debris, ensuring your tools stay functional for longer periods.

Consulting tutorials for step-by-step instructions on the correct soaking methods will ensure that you achieve the best results and extend the lifespan of your tools. Proper soaking can save time and effort by streamlining the cleaning process and maintaining the tools’ integrity.

Scrub Tools With Scraper

Scrub your plastering tools with a scraper to remove dissolved plaster residues and ensure a clean surface. Implementing proper cleaning tips can enhance the efficiency of this scrubbing process.

One of the essential tips for effective cleaning is to soak your tools in warm, soapy water to help soften the hardened residues before scrubbing. Using a wire brush alongside the scraper can aid in tackling stubborn build-ups.

Another useful tip is to regularly inspect your tools for any signs of wear and tear, as damaged tools can hinder the cleaning process. Ensuring that the scraper’s edge is sharp will also make the scrubbing more efficient.

Rinse Tools Thoroughly

Thoroughly rinse your plastering tools with water to remove any remaining cleaning solution and ensure they are ready for the next use.

Following recommendations from experts can truly enhance your rinsing technique. Proper rinsing is crucial to prevent any residue from cleaning materials left on your tools, which could affect the quality of your work. By incorporating efficient rinsing practices, you not only maintain the longevity of your tools but also ensure a smooth workflow during your plastering projects.

Dry Tools Completely

After rinsing, dry your plastering tools completely to prevent rust or damage. This step is crucial, especially on a busy construction site where tools are frequently in use.

Drying tools thoroughly is not just about preventing rust; it’s also vital for maintaining their quality and prolonging their lifespan. Moisture trapped in the tools can lead to corrosion over time, impacting their performance on the construction site. Proper drying techniques, such as using absorbent cloths or air drying in a well-ventilated area, can make a significant difference.

Store Tools Properly

Proper storage of cleaned plastering tools is essential to preserve their quality and extend their lifespan. Ensuring they are stored in a dry and secure location can prevent damage and maintain their functionality.

When tools are not stored correctly, they are prone to rust, corrosion, and wear, diminishing their effectiveness over time. By investing time in organizing a designated storage space for your tools, you protect your investment and ensure they are always ready for use. Storing tools vertically in racks or pegboards can help to prevent contact between them, reducing the risk of scratches and dents. Keeping them in a climate-controlled environment can further safeguard them from the elements, ensuring they remain in optimal condition.

How Often Should Plastering Tools Be Cleaned?

The frequency of cleaning plastering tools will depend on the intensity of their use, with tools on a busy construction site requiring more frequent cleaning to maintain efficiency and performance.

In a high-intensity construction setting, water consumption can play a crucial role in determining cleaning frequency. Dust, debris, and other materials can quickly accumulate on plastering tools in such environments, necessitating regular cleaning to prevent clogging and ensure smooth operation.

Factors like humidity levels and temperature variations at the construction site can impact the rate at which plastering tools need cleaning. Higher humidity can lead to faster drying times of plaster and other materials, potentially requiring more frequent tool cleaning.

What Are Some Tips For Maintaining Plastering Tools?

To keep your plastering tools in optimal condition, consider implementing maintenance tips and techniques provided by experts in the field. These tips can enhance the longevity and performance of your tools.

One crucial aspect of tool maintenance is to regularly clean your plastering tools after each use. The build-up of hardened plaster can damage the tool’s surface and hinder its functionality.

Proper cleaning can prevent corrosion and ensure smooth operation. Storing your tools in a dry environment can prevent rust and decay. Another important technique for tool care is to inspect them for any signs of wear and tear regularly. Addressing issues early can prevent further damage and save you time and money in the long run.