Wondering if you can give your old leather jacket a new lease on life with a fresh coat of dye?

We explore the possibilities of dyeing a leather jacket, including the types of leather that can be dyed and the various types of dyes available.

We also discuss the supplies you will need and provide a step-by-step guide on how to successfully dye your leather jacket.

If you’re ready to give your favorite jacket a makeover, keep reading to find out how!

Can You Dye a Leather Jacket?

Dyeing a leather jacket is a feasible and rewarding process that can breathe new life into an old or faded piece of clothing, making it look brand new with the right type of leather dye and proper application techniques.

What Types of Leather Can Be Dyed?

Not all types of leather can be dyed effectively, but many common types found in consumer products are suitable for the dyeing process, including aniline, semi-aniline, and pigmented leather.

Discover: Can You Dye A Leather Sofa

What is Aniline Leather?

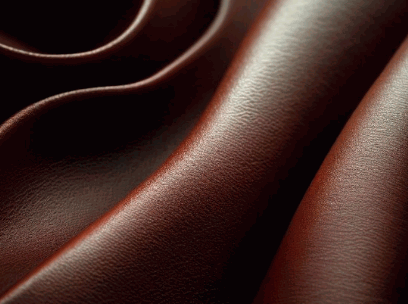

Aniline leather is a type of high-quality leather that is dyed using soluble dyes without covering the surface with a topcoat or pigment, allowing the natural grain to show through.

This type of leather is known for its softness and luxurious feel, as the dyeing process retains the hide’s natural characteristics, such as wrinkles, marks, and blemishes, making each piece unique in its appearance. Aniline leather tends to develop a rich patina over time, enhancing its beauty and giving it a distinguished vintage look.

What is Semi-Aniline Leather?

Semi-aniline leather is dyed similarly to aniline leather but includes a slight protective finish that makes it more resistant to stains and wear while maintaining a natural look.

One of the key characteristics of semi-aniline leather is its balance between durability and natural aesthetics. It retains the luxurious feel of aniline leather while offering improved protection against daily wear and tear. This type of leather is often sought after for furniture and high-end car interiors due to its enhanced practicality.

The advantages of semi-aniline leather over pure aniline leather include increased resistance to fading and staining, making it a popular choice for areas with higher exposure to sunlight or heavy use. The dyeing process of semi-aniline leather allows for a wider range of color options compared to aniline leather, giving designers more flexibility to achieve specific looks.

The dyeing process in semi-aniline leather involves lightly pigmented dyes that penetrate the surface, enhancing the color depth while still allowing the natural grain to show through. The result is a rich, deep color that doesn’t compromise the leather’s inherent texture and characteristics. This process also helps retain the softness and suppleness of the leather, making it comfortable to touch while maintaining its durability.

What is Pigmented Leather?

Pigmented leather is treated with a solid layer of pigment and a protective coating, making it the most durable and easy to maintain among dyed leathers, commonly used in leather items like furniture and car interiors.

This type of leather is ideal for high-traffic areas due to its resistance to stains, scratches, and fading. Its protective coating acts as a barrier against spills and everyday wear and tear. With proper care, pigmented leather can maintain its appearance for years, requiring only regular dusting and occasional cleaning with a damp cloth. Dyeing pigmented leather can offer a variety of colors and finishes, enhancing its aesthetic appeal and allowing for customization to suit different interior styles.

What Types of Dyes Can Be Used on Leather?

Various types of dyes can be used to color leather items, including leather dye, leather paint, and leather stain, each serving different purposes and offering unique finishes in the dyeing process.

What is Leather Dye?

Leather dye penetrates deep into the leather fibers to change the color permanently, providing a vibrant and long-lasting finish suitable for various leather items.

One of the key properties of leather dye is its ability to bond with the leather and become an integral part of its structure, rather than just sitting on the surface like paint or coatings. This ensures that the color remains fade-resistant and does not peel or crack over time.

The benefits of using leather dye extend beyond its color-changing capabilities. It can also help to restore old or worn-out leather items, giving them a fresh and renewed appearance.

When applying leather dye, it is important to prep the surface by cleaning it thoroughly to remove any dirt or oils that could interfere with the dye’s absorption. Following the manufacturer’s instructions on application techniques and drying times is crucial for achieving the best results.

Leather dye is particularly well-suited for items like furniture, shoes, belts, handbags, and even car interiors. Its versatility and durability make it a popular choice for leather enthusiasts looking to customize or revive their leather goods.

What is Leather Paint?

Leather paint sits on the surface of the leather and is ideal for adding custom designs or changing the color of finished leather, providing a smooth and even leather finish.

Unlike leather dye, which penetrates the leather fibers, leather paint forms a protective layer on top of the material. The application of leather paint involves using a brush or airbrush to carefully coat the leather surface with the desired color. This method allows for intricate designs and detailed patterns to be created with precision. Leather paint offers excellent coverage, ensuring vibrant and opaque colors. Leather paint often provides a glossy or matte finish, depending on the product used, giving the leather a distinct and personalized appearance.

What is Leather Stain?

Leather stain is used to enhance the natural beauty of the leather, adding depth and richness to the color without obscuring the natural grain or texture of the leather surface.

When applied correctly, leather stain can bring out the character and uniqueness of each piece, creating a luxurious and personalized look. The application of leather stain is a crucial step in the dyeing process, as it penetrates the fibers of the leather, ensuring long-lasting color that resists fading. By carefully selecting the right shade of stain, whether it’s a classic brown or a bold red, you can transform the appearance of your leather items while preserving their quality.

What Supplies Do You Need to Dye a Leather Jacket?

Dyeing a leather jacket requires a specific set of supplies, including leather dye or paint, leather preparer, leather finisher, protective gloves, brushes or sponges, plastic wrap, and old towels or newspaper to ensure a smooth and professional result.

Leather Dye or Paint

Choosing between leather dye and leather paint depends on the desired color effect and type of leather item being dyed; both have their unique applications and benefits.

Regarding leather dye, it penetrates deep into the leather fibers, resulting in a long-lasting color that doesn’t peel or crack. On the other hand, leather paint sits on the surface of the leather, providing a more opaque and customizable color finish. Leather dye is ideal for changing the color of the leather while maintaining its natural texture, whereas leather paint is great for intricate designs or covering stains. Consider the type of leather item you’re working with – for furniture or large surfaces, dye may offer a more seamless finish, whereas paint may be more suitable for smaller items or projects requiring precise detailing.

Leather Preparer

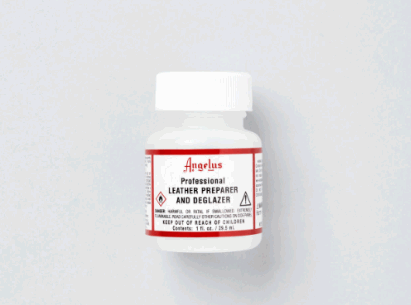

A leather preparer is essential for cleaning and preparing the leather surface by removing old finishes, dirt, and oils, ensuring better dye adhesion.

It plays a crucial role in achieving a uniform and professional-looking finish on your leather projects. By using a leather preparer, you can ensure that the dye will penetrate evenly, resulting in a vibrant and long-lasting color.

When applying a leather preparer, it’s important to follow the manufacturer’s instructions carefully. Usually, you will need to apply the preparer with a clean cloth, gently rubbing it onto the surface to remove accumulated grime and oils.

Allow the preparer to dry completely before proceeding with the dye application to guarantee optimal results.

Leather Finisher

A leather finisher is applied as a final coat to protect the dyed leather and provide a desired finish, such as glossy, matte, or satin.

There are various types of leather finishers available in the market, each serving a unique purpose. Some finishers contain protective components that shield the leather from moisture, stains, and scratches, enhancing its longevity.

Others are formulated to alter the sheen level of the leather, giving it a lustrous shine or a subtle matte appearance, depending on the desired aesthetic.

These finishers play a crucial role in maintaining the overall look and feel of the leather while ensuring it remains durable and resistant to wear and tear.

Protective Gloves

Wearing protective gloves during the dyeing process is crucial to protect your hands from the chemicals in the dye and prevent any accidental staining.

Not only do protective gloves shield your skin from direct contact with potentially harmful substances, but they also provide a barrier against any allergic reactions or irritation that may arise from exposure.

When selecting the right pair of gloves for dyeing, consider the type of dye you are using and the level of protection required. Nitrile gloves are often a good choice for their resistance to chemicals, while latex gloves offer flexibility. Ensure the gloves fit properly to avoid any accidents during the dye application process.

Brushes or Sponges

Brushes or sponges are used to apply the dye in thin layers, ensuring even coverage and a smooth finish by working in a circular motion.

When choosing brushes for leather dyeing, opt for soft bristle brushes that allow for a controlled application, preventing streaks or smudges on the leather surface. Sponges, on the other hand, can be ideal for larger surface areas or intricate designs, as they provide a more seamless and consistent distribution of dye. To apply the dye evenly, start from the center of the leather piece and gradually work your way outwards, ensuring no patchy areas are left untreated.

Plastic Wrap

Plastic wrap can be used to cover leather items during the dyeing process to protect areas that should not be dyed and to maintain a controlled environment.

Plastic wrap serves as a barrier between the leather and any accidental spills or splashes, preventing unwanted stains. It is a versatile tool that can also be used to create marbling effects on leather by manipulating the plastic wrap before the dye sets. When dyeing intricate patterns, using plastic wrap can help blend colors smoothly and prevent bleeding. To effectively utilize plastic wrap in leather dyeing, ensure that it is tightly secured around the item to avoid any seepage of dye onto protected areas.

Old Towels or Newspaper

Old towels or newspapers are handy for protecting your work area and cleaning up spills during the dyeing process, ensuring a tidy workspace.

When dyeing fabrics or materials, spills are almost inevitable, and having old towels or newspapers nearby can save you from unwanted messes. These materials absorb excess dye and liquid, preventing stains on your work surface or clothes. By placing them strategically around your dyeing station, you create a barrier that not only protects your surroundings but also makes the cleaning process much easier.

Old towels or newspapers also help in maintaining a clean and organized workspace, which is crucial for a successful dyeing project. They enable you to focus on the creative aspect of dyeing without worrying about potential spills or stains. Having designated areas for different tasks, such as cutting, mixing dyes, and drying fabrics, can streamline your workflow and improve efficiency.

How to Dye a Leather Jacket?

Dyeing a leather jacket involves several key steps, including preparing the leather, applying the dye, and finishing the process to ensure a professional and long-lasting result.

Preparing the Leather

Preparing the leather involves cleaning it thoroughly with a leather preparer and a clean cloth to remove any dirt, oils, or old finishes, and conditioning it to ensure it is supple and ready for dyeing.

Once the leather is cleaned and conditioned, it is essential to let it dry completely before proceeding to the dyeing process. This will help the dye to adhere evenly and prevent any blotches or uneven coloring. When applying the dye, start with thin layers and build up gradually for a more uniform finish. It’s recommended to use a sponge or brush for application, ensuring even coverage across the entire surface of the leather.

Applying the Dye

Applying the dye should be done in thin, even layers using a brush or sponge, working in a circular motion to ensure thorough coverage and avoid streaks.

When applying the dye, it’s crucial to start with a small amount of product on your brush or sponge to prevent over-saturation.

- Begin in an inconspicuous area to test the color and absorption of the material.

- Work systematically, moving across the surface in sections to maintain consistency.

- For a professional finish, make sure to blend any overlapping areas to avoid noticeable transitions.

By building up the color gradually, you’ll achieve a more even and natural look, enhancing the overall aesthetic of the dyed surface.

Finishing the Process

Finishing the process involves applying a leather finisher or sealer as a final coat to protect the dyed leather and allow it to dry completely, ensuring a durable and polished result.

Once the dyeing process is complete, the next step is choosing the appropriate finisher or sealer for the type of leather used. Common types include acrylic sealers, wax finishers, and oil-based finishers, each offering unique benefits. It’s crucial to follow the manufacturer’s instructions for application to achieve optimal results. To ensure the dyed leather is well-protected, proper drying is essential. Allow the leather to dry naturally in a well-ventilated area, avoiding direct sunlight or heat sources that could damage the finish. Regularly check the leather for any signs of cracking or peeling, and apply additional coats if necessary to maintain its integrity.